Detailed Introduction to the Selection of GCC-PS603-RD809 80G High-Frequency Radar Level Gauge - Comprehensive Analysis of Technical Parameters, Scene Adaptation, and Selection Key Points

Model: GCC-PS603-RD809

Minimum order: 10

Temperature: -40~+100℃

Medium: Solid materials such as granules, blocks, and powders

Pressure: -0.1~+0.1MPa

Installation method:

Measurement range: 0~10m/20m/30m/60m/120m

Output signal: 4~20mA/HART/RS485

Measurement accuracy: ±1mm

Material:

<

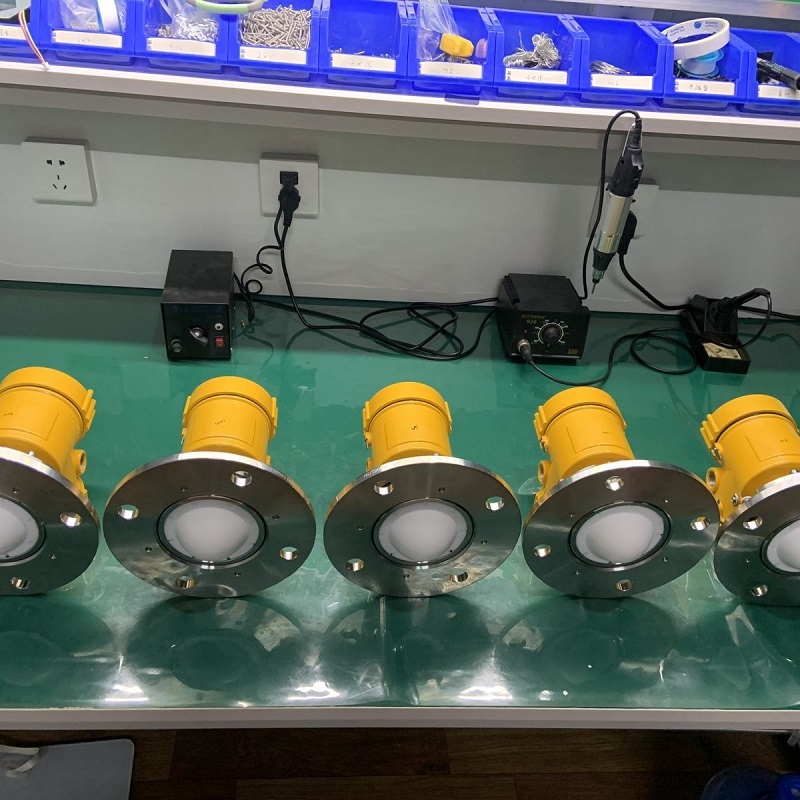

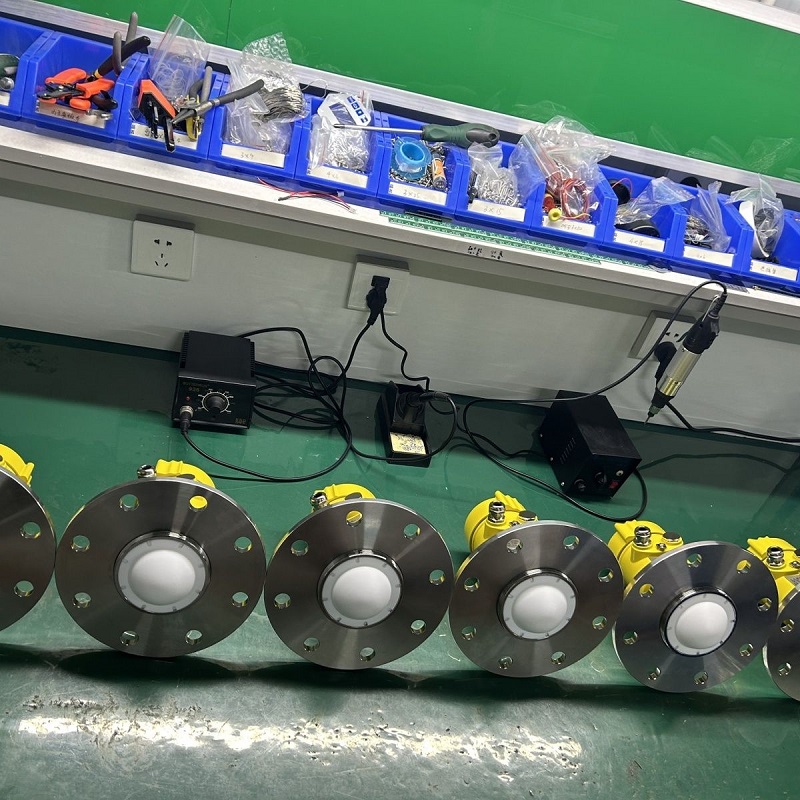

Current Image: 011301.jpg

Click thumbnails to switch product images

Detailed Selection Guide for GCC-PS603-RD809 80G High-Frequency Radar Level Gauge

Core Selection Highlights

Operating Frequency: 80GHz (76-81GHz) Frequency Modulated Continuous Wave (FMCW), shorter wavelength, narrow beam angle (≤2°)

Measurement Accuracy: ±1mm, ideal for high-precision liquid level monitoring scenarios

Range: Standard 0-30m, expandable up to 150m, suitable for various storage tanks

Core Advantages: Non-contact measurement, strong anti-interference capability, minimal blind zone (≤3cm), corrosion resistance

Applicable Working Conditions: Complex industrial environments such as chemical, petroleum, electric power, metallurgy industries; especially suitable for low dielectric constant media, high-temperature and high-pressure scenarios

1. Product Overview and Core Advantages

1.1 Product Positioning

The GCC-PS603-RD809 is an 80G high-frequency radar level gauge independently developed by Anhui Chuchen Technology Co., Ltd. Based on FMCW technology, it is specially designed for high-precision liquid level measurement in industrial processes. It is applicable to liquid level monitoring of various storage tanks, reactors, tanks and other containers, and performs excellently in complex working conditions.

1.2 Core Technical Advantages

Advantage Category | Specific Features | Selection Value |

Measurement Accuracy | ±1mm, resolution up to 0.1mm | Meets the requirements of trade settlement and accurate inventory management |

Beam Characteristics | Beam angle ≤2°, concentrated energy | Avoids obstacles such as stirrers and coils, suitable for complex tank structures |

Anti-interference Capability | 80GHz high-frequency signal with strong penetration of steam, foam and dust | Applicable to working conditions with heavy dust, high foam and strong steam |

Non-contact Measurement | No direct contact with the medium | Suitable for corrosive, high-viscosity, toxic and harmful media, maintenance-free |

Blind Zone Design | Blind zone ≤3cm | Suitable for small storage tanks and low liquid level measurement scenarios |

Flexible Installation | Supports top-mounted/side-mounted installation with multiple process connection methods | Adapts to containers of different specifications with low requirements for installation space |

2. Detailed Technical Parameters (Core Basis for Selection)

2.1 Basic Measurement Parameters

Parameter Item | Technical Index | Selection Reference |

Operating Frequency | 80GHz (76-81GHz) FMCW | High-frequency signals are suitable for low dielectric constant media (e.g., liquefied gas) |

Measurement Range | Standard 0-30m, maximum 150m | Select the model with 20% margin based on the tank height |

Measurement Accuracy | ±1mm (standard working condition) | First choice for high-precision scenarios such as oil tanks and chemical raw material tanks |

Repeatability | ±0.5mm | Ensures long-term measurement stability |

Response Time | 0.1-10s (adjustable) | Quickly responds to liquid level changes, suitable for dynamic production processes |

Blind Zone | ≤3cm | Reserve ≥5cm installation height for small storage tanks |

Antenna Type | Optional horn antenna/parabolic antenna | Horn antenna for general use, parabolic antenna for long-distance measurement |

2.2 Process Condition Parameters

Parameter Item | Technical Index | Applicable Scenario |

Operating Temperature | -40℃~+150℃ (standard), expandable to +250℃ | Suitable for normal to high-temperature working conditions such as oil refineries and chemical plants |

Operating Pressure | -0.1MPa~+4.0MPa | Vacuum to high-pressure containers such as reactors and high-pressure storage tanks |

Protection Grade | IP67/IP68 | Outdoor installation, humid environments, short-term underwater immersion |

Explosion-proof Rating | Ex d IIB T6 Gb/Ex ia IIC T4 Ga | Flammable and explosive places such as chemical and petroleum industries |

Material Selection | Housing: Cast aluminum/316L stainless steelAntenna: PTFE/316L stainless steel | 316L + PTFE material is required for corrosive media |

2.3 Electrical and Communication Parameters

Parameter Item | Technical Index | Selection Points |

Power Supply Mode | Two-wire system (24VDC) / Four-wire system (24VDC/220VAC) | Two-wire system is suitable for explosion-proof scenarios, four-wire system has more abundant functions |

Output Signal | 4-20mA+HART, RS485 (Modbus RTU), Wireless HART optional | Adapts to DCS, PLC and other control systems, supports remote monitoring |

Communication Protocol | HART7.0, Modbus RTU | Ensure compatibility with existing systems |

Load Capacity | Two-wire system: ≤500ΩFour-wire system: ≤1000Ω | Match the system load to avoid signal distortion |

3. Core Selection Elements and Steps

3.1 Five-step Selection Method (Ensure Accurate Matching)

Step 1: Medium Characteristic Analysis (Key First Step)

Dielectric Constant (εr): For media with low dielectric constant (εr<1.8, such as liquefied gas), 80G high-frequency radar must be selected for strong signal reflection.

Corrosiveness: For highly corrosive media (such as acids and alkalis), 316L stainless steel + PTFE antenna material should be selected.

Viscosity: For high-viscosity media (>1000cP), non-contact type is recommended to avoid material hanging affecting measurement.

Temperature/Pressure: Confirm whether the working temperature and pressure of the medium are within the product parameter range; customization is required if exceeding the range.

Step 2: Working Condition Environment Evaluation

Interference Factors: Severe steam, foam, dust → 80G high-frequency radar is preferred for its strong penetration ability.

Agitation Condition: If there is a stirrer → select the model with beam angle ≤2° to avoid the stirring paddle.

Installation Space: For narrow space → select miniaturized antenna that supports side-mounted installation.

Explosion-proof Requirements: For flammable and explosive places → explosion-proof rating of Ex d IIB T6 or higher must be selected.

Step 3: Confirmation of Measurement Requirements

Accuracy Requirement: For trade settlement and precise measurement → select the model with ±1mm accuracy.

Range Calculation: Actual liquid level height + 20% margin (e.g., 10m tank → select 12m range).

Output Signal: Select 4-20mA+HART, RS485, etc., according to the control system.

Communication Protocol: Ensure compatibility with DCS/PLC.

Step 4: Installation Method Selection

Installation Method | Applicable Scenario | Selection Points |

Top-mounted Flange | Vertical storage tanks, reactors | Flange specifications: DN50/DN80/DN100, pressure rating PN16/PN40 |

Side-mounted Thread | Horizontal storage tanks, small tanks | Thread specifications: G1½", NPT1½", confirm that there is no blind zone at the installation position |

Waveguide Installation | Strong interference, low dielectric constant media | Use with waveguide to improve measurement stability |

Step 5: Additional Function Configuration

Display Function: On-site display and button operation → select the model with LCD display.

Alarm Function: High/low liquid level alarm → configure relay output.

Remote Monitoring: 4G/NB-IoT wireless transmission → suitable for smart factories and unattended scenarios.

Explosion-proof Certificate: Explosion-proof certification corresponding to the hazardous location must be provided.

3.2 Selection Taboos and Precautions

Avoid Selection Errors:

Selecting low-frequency radar (6GHz/26GHz) for low dielectric constant media → weak signal reflection leads to inaccurate measurement.

Selecting guided wave radar for high-viscosity media → material hanging is easy to affect measurement accuracy.

Selecting radar with large beam angle for narrow space → signals are easily reflected and interfered by the tank wall.

Key Parameter Verification:

The range must be ≥ actual liquid level height + 20% margin.

The working temperature/pressure shall not exceed the rated value of the product.

The explosion-proof rating must match the hazard zone classification of the use site.

4. Typical Application Scenarios and Adaptation Schemes

4.1 Chemical Industry

Application Case: Liquid level measurement of acid-base storage tanks and reactors

Selection Scheme: GCC-PS603-RD809 (316L + PTFE material, Ex d IIB T6 explosion-proof, ±1mm accuracy)

Core Advantages: Corrosion resistance, strong anti-interference, suitable for strong acid-base, high-temperature and high-pressure working conditions

4.2 Petrochemical Industry

Application Case: Liquid level measurement of crude oil storage tanks, refined oil storage tanks and liquefied gas storage tanks

Selection Scheme: GCC-PS603-RD809 (80G high frequency, ±1mm accuracy, DN80 flange installation)

Core Advantages: Accurate measurement of low dielectric constant media, meeting the requirements of trade settlement

4.3 Electric Power Industry

Application Case: Liquid level measurement of desulfurization towers, slurry tanks and demineralized water tanks

Selection Scheme: GCC-PS603-RD809 (anti-dust, anti-foam, 4-20mA+HART output)

Core Advantages: Strong penetration of dust and foam, stable measurement

4.4 Metallurgical Industry

Application Case: Liquid level measurement of blast furnace slag tanks, combustion improver storage tanks and acid-base washing tanks

Selection Scheme: GCC-PS603-RD809 (high-temperature type, -40℃~+250℃, IP68 protection)

Core Advantages: High temperature resistance, corrosion resistance, suitable for harsh industrial environments

4.5 Water Treatment Industry

Application Case: Liquid level measurement of clear water tanks, sewage tanks and chemical storage tanks

Selection Scheme: GCC-PS603-RD809 (standard type, IP67 protection, side-mounted thread installation)

Core Advantages: Flexible installation, simple maintenance, suitable for liquid level measurement of various water tanks

5. Installation and Maintenance Points (Selection Extension)

5.1 Key Installation Precautions

Installation Position:

Distance from the tank wall ≥ 1/6 of the tank diameter and ≥ 200mm to avoid reflection interference from the tank wall.

Keep away from obstacles such as stirrers, coils and ladders with a distance ≥ 300mm.

Ensure that the antenna is perpendicular to the liquid surface when top-mounted, and pay attention to the measurement blind zone when side-mounted.

Environmental Requirements:

A sunshade shall be added for outdoor installation to avoid direct sunlight affecting electronic components.

Installation in explosion-proof places shall comply with explosion-proof specifications, and cables shall pass through explosion-proof pipes.

Power supply stability: Voltage fluctuation ≤ ±10%, it is recommended to install a surge protector.

5.2 Maintenance and Calibration

Daily Maintenance: Clean the antenna surface regularly (once a month) and check the connection tightness.

Calibration Cycle: Generally calibrated once every 6 months, and once every 3 months for key measurement points.

Troubleshooting: No signal → check power supply, antenna cleanliness and installation position; inaccurate measurement → recalibrate and check the change of medium characteristics.

6. Selection Comparison Table (80G vs 26G vs 6G Radar)

Comparison Item | GCC-PS603-RD809 (80G) | 26G Radar | 6G Radar | Selection Suggestion |

Operating Frequency | 80GHz | 26GHz | 6GHz | Select 80G for low dielectric constant media, 26G for standard working conditions, 6G for simple scenarios |

Beam Angle | ≤2° | 8°-10° | 15°-20° | Select 80G for complex tank structures to avoid obstacles |

Measurement Accuracy | ±1mm | ±5mm | ±10mm | Select 80G for high-precision requirements, 26G for general control |

Blind Zone | ≤3cm | ≤10cm | ≤30cm | Select 80G for small storage tanks, 26G/6G for large storage tanks |

Anti-interference Capability | Extremely strong (penetrating steam/foam/dust) | Strong | General | Select 80G for high-interference working conditions, 26G for standard working conditions |

Price Range | Medium-high | Medium | Low | Select 80G for sufficient budget and complex working conditions, 26G/6G for cost-sensitive scenarios |

7. Selection Summary and Recommended Configuration

7.1 Selection Decision Tree

Medium dielectric constant < 1.8 → 80G radar must be selected (GCC-PS603-RD809)

Accuracy requirement ≤ ±1mm → 80G radar must be selected

Working conditions with strong steam/foam/dust → 80G radar is preferred

Tanks with stirrers/coils → 80G radar is preferred (beam angle ≤2°)

Standard working conditions + general accuracy → 26G radar is optional

Simple scenarios + cost-sensitive → 6G radar is optional

7.2 Recommended Standard Configuration

Basic Model: GCC-PS603-RD809-30M-DN80-PTFE

Range: 30m, Flange DN80, PTFE antenna, Accuracy ±1mm, Explosion-proof Ex d IIB T6

Application: Standard tank measurement in chemical and petroleum industries

High-temperature Model: GCC-PS603-RD809-30M-DN80-316L-H

Range: 30m, Flange DN80, 316L stainless steel + PTFE antenna, High temperature resistance up to +250℃

Application: High-temperature tank measurement in oil refineries and metallurgical industries

Enhanced Explosion-proof Model: GCC-PS603-RD809-30M-DN80-Exia

Range: 30m, Flange DN80, Explosion-proof rating Ex ia IIC T4

Application: Hazardous location 0 in chemical and pharmaceutical industries

Selection Consultation: Anhui Chuchen Technology provides professional selection services, and can provide customized selection schemes free of charge according to your specific working conditions. Contact Phone: 15212084600, Email: 394821307@qq.com.

Send Inquiry