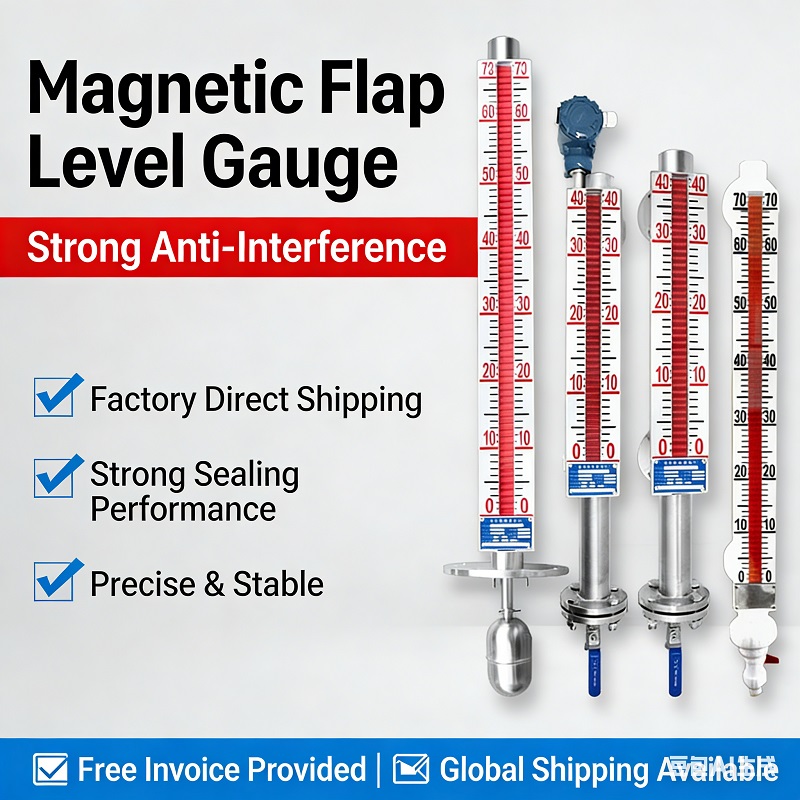

UHZ-158S-UK Insertion Type Magnetic Level Gauge | No-Shutdown Installation for Industrial Tanks

Model: UHZ-158S-UK

Minimum order: 10

Temperature: -10~80℃

Medium: Solid materials such as granules, blocks, and powders

Pressure: ≤1.0MPa

Installation method:

Measurement range: 300~6000mm

Output signal: Switch signal (1~4 points selectable, normally open/normally closed customizable)

Measurement accuracy: ±10mm

Material: Stainless Steel 304/316L/PTFE

<

Current Image: 英文011301.jpg

Click thumbnails to switch product images

Core Product Highlights

Installation Type: Insertion design, no tank shutdown required for installation/disassembly, reducing production downtime

Measurement Principle: Magnetic coupling, non-contact signal transmission, stable performance without medium pollution

Applicable Media: Various liquids (acid, alkali, oil, water, etc.), compatible with corrosive/viscous media

Protection Grade: IP67/IP68, suitable for outdoor, humid, and harsh industrial environments

Output Signal: 4-20mA/HART, RS485 (Modbus RTU) optional, seamless integration with DCS/PLC systems

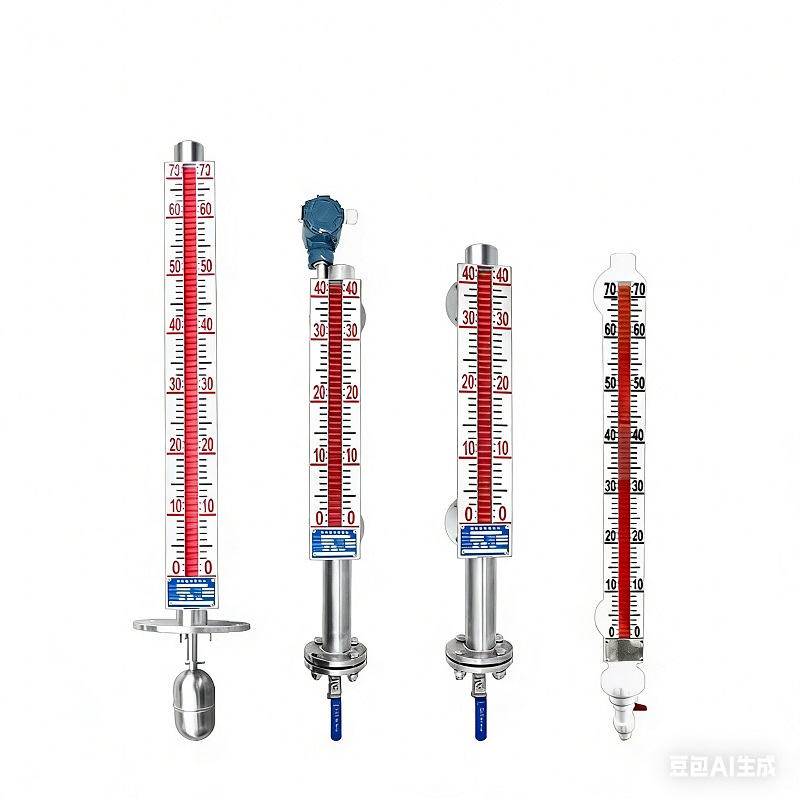

1. Product Overview & Working Principle

The UHZ-158S-UK Insertion Type Magnetic Level Gauge is a cost-effective liquid level measurement device independently developed by Anhui Chuchen Technology Co., Ltd. Designed for industrial tanks, reactors, and storage vessels, this gauge solves the pain point of traditional level gauges requiring tank shutdown for installation. It is widely used in chemical, petroleum, electric power, and water treatment industries for real-time liquid level monitoring.

1.2 Working Principle

The UHZ-158S-UK adopts magnetic coupling technology:

Insert the measuring probe into the tank through a pre-installed flange or threaded port (no need to empty the tank).

The magnetic float inside the probe rises and falls with the liquid level.

The magnetic signal is transmitted to the external indicator panel through the isolation layer, driving the magnetic flap to flip and display the real-time liquid level.

The built-in transmitter converts the level signal into a standard 4-20mA electrical signal for remote monitoring and control.

2. Core Technical Advantages

Advantage Category Specific Features Application Value

No-shutdown Installation Insertion structure, installable during tank operation Eliminates production downtime, reduces maintenance costs by 30%

Non-contact Transmission Magnetic coupling, no direct contact between indicator and medium Avoids medium pollution and corrosion damage to the gauge

Wide Media Compatibility Compatible with acids, alkalis, oils, water, and high-viscosity media One device for multiple scenarios, suitable for complex industrial environments

High Reliability No moving parts in the external indicator, IP67/IP68 protection Long service life (≥5 years), stable performance in harsh conditions

Dual Display Function On-site visual indicator + remote electrical signal output Meets both on-site inspection and centralized control requirements

3. Detailed Technical Parameters

3.1 Basic Measurement Parameters

Parameter Item Technical Index of UHZ-158S-UK Selection Reference

Measurement Range 0-1m, 0-2m, 0-3m, 0-5m (customizable up to 10m) Select range according to the actual liquid level variation of the tank

Measurement Accuracy ±5mm (standard), ±2mm (high-precision version) Standard version for general control; high-precision for precise measurement

Indicator Resolution 10mm Clear visual reading, easy on-site inspection

Float Material 316L stainless steel, PTFE-coated stainless steel PTFE coating for strong corrosive media (e.g., hydrochloric acid, sulfuric acid)

Probe Diameter DN25, DN32, DN40 Small diameter (DN25) for narrow installation space; large diameter for high-viscosity media

3.2 Process Condition Parameters

Parameter Item Technical Index Applicable Scenario

Operating Temperature -40℃~+150℃ (standard), -40℃~+250℃ (high-temperature version) Standard for normal industrial environments; high-temperature for oil refineries, metallurgical plants

Operating Pressure 0-1.6MPa (standard), 0-6.4MPa (high-pressure version) Standard for atmospheric tanks; high-pressure for reactors and high-pressure storage tanks

Medium Viscosity ≤500cP (standard), ≤2000cP (high-viscosity version) High-viscosity version for media such as crude oil, resin, and syrup

Protection Grade Indicator: IP67; Probe: IP68 Indicator suitable for outdoor installation; probe can be immersed in liquid for long-term use

Explosion-proof Rating Ex d IIB T6 Gb (optional) Applicable to flammable and explosive places (e.g., petroleum depots, chemical workshops)

3.3 Electrical Parameters

Parameter Item Technical Index Matching Suggestion

Power Supply 24VDC (two-wire system) Compatible with most industrial power supplies

Output Signal 4-20mA+HART (standard), RS485 (Modbus RTU) (optional) 4-20mA+HART for DCS integration; RS485 for digital communication

Load Resistance 250-500Ω (for 4-20mA signal) Ensure load resistance matches to avoid signal distortion

Response Time ≤1s Real-time tracking of liquid level changes

4. Core Selection Guide for UHZ-158S-UK

4.1 Selection Step-by-Step Method

Step 1: Confirm Tank & Medium Characteristics

Tank Type: Atmospheric tank / high-pressure tank / reactor → select corresponding pressure version of UHZ-158S-UK

Medium Corrosiveness: Non-corrosive (water, oil) → 316L float; corrosive (acid, alkali) → PTFE-coated float

Medium Viscosity: ≤500cP → standard version; >500cP → high-viscosity version with large-diameter probe

Step 2: Determine Measurement Requirements

Accuracy Requirement: General control (±5mm) → standard version; precise measurement (±2mm) → high-precision version

Output Signal Requirement: On-site display only → no transmitter; remote monitoring → select 4-20mA/HART or RS485 version

Explosion-proof Requirement: Normal environment → non-explosion-proof; flammable and explosive environment → Ex d IIB T6 version

Step 3: Select Installation Accessories

Connection Type: Flange connection (DN25/DN32/DN40) / threaded connection (G1", NPT1") → match tank interface

Insertion Depth: Calculate based on tank height and liquid level variation range → reserve 100mm margin at the bottom

Protection Accessories: Sunshade cover (outdoor installation) / anti-freezing jacket (low-temperature environment) → according to installation environment

4.2 Selection Taboos & Precautions

Avoid Inappropriate Version Selection

Do not use standard version for high-pressure tanks → risk of probe rupture and medium leakage

Do not use non-PTFE float for strong corrosive media → float corrosion leads to measurement failure

Do not use standard version for high-viscosity media → float jamming affects liquid level tracking

Key Parameter Verification

Ensure the measurement range covers the full variation range of the liquid level (reserve 20% margin)

Confirm the operating temperature/pressure of the gauge matches the actual working conditions of the tank

Check the compatibility between the output signal and the on-site control system (DCS/PLC)

5. Typical Application Scenarios

5.1 Chemical Industry

Application Case: Liquid level measurement of acid-base storage tanks, chemical raw material tanks

Selection Scheme: UHZ-158S-UK (PTFE float, IP68 probe, Ex d IIB T6 explosion-proof)

Core Value: No-shutdown installation avoids production interruption; corrosion-resistant design ensures long-term stable operation

5.2 Petroleum Industry

Application Case: Liquid level measurement of crude oil tanks, refined oil tanks

Selection Scheme: UHZ-158S-UK (high-viscosity version, DN40 probe, 4-20mA+HART output)

Core Value: Adapts to high-viscosity crude oil; remote output realizes centralized monitoring of oil depots

5.3 Electric Power Industry

Application Case: Liquid level measurement of boiler water tanks, demineralized water tanks

Selection Scheme: UHZ-158S-UK (standard version, IP67 indicator, RS485 output)

Core Value: High reliability meets the continuous operation requirements of power plants; digital communication integrates with power plant control systems

5.4 Water Treatment Industry

Application Case: Liquid level measurement of clear water tanks, sewage tanks, chemical dosing tanks

Selection Scheme: UHZ-158S-UK (standard version, 316L float, threaded connection)

Core Value: Cost-effective; easy installation and maintenance; suitable for large-scale water treatment projects

6. Installation & Maintenance Guidelines

6.1 Key Installation Steps (No-shutdown Operation)

Preparation Work: Check the UHZ-158S-UK model and accessories; prepare installation tools (wrench, flange gasket, etc.)

Interface Connection: Install the connecting flange/threaded port on the tank wall (ensure the installation position is above the lowest liquid level)

Probe Insertion: Insert the UHZ-158S-UK probe into the tank through the interface; tighten the flange bolts to ensure sealing

Indicator Installation: Fix the external indicator panel on the tank wall or a nearby bracket; ensure the indicator is perpendicular to the ground

Wiring Configuration: Connect the transmitter to the power supply and control system (follow the wiring diagram to avoid reverse connection)

Commissioning: Turn on the power; check the on-site indicator and remote signal to ensure consistent and accurate liquid level display

6.2 Installation Precautions

Insertion Depth: The probe must reach below the lowest liquid level (reserve 100mm margin) to ensure full-range measurement

Sealing Requirement: Use high-quality flange gaskets; tighten bolts evenly to avoid medium leakage

Indicator Position: Install the indicator in a place easy to inspect; avoid direct sunlight and heavy rain (add a sunshade for outdoor installation)

Explosion-proof Installation: In hazardous areas, use explosion-proof cables and junction boxes; comply with local explosion-proof regulations

6.3 Maintenance & Troubleshooting

Daily Maintenance

Visual Inspection: Check the indicator panel for damage and the float for jamming once a week

Cleaning: Clean the probe surface and indicator panel once a month (use a soft cloth; avoid corrosive cleaning agents)

Calibration: Calibrate the gauge once every 6 months (compare with a standard level gauge to ensure measurement accuracy)

Common Faults & Solutions

Fault Phenomenon Possible Causes Solutions

No display on indicator Power failure / float jamming Check power supply; remove the probe and clean the float

Inconsistent on-site and remote signals Wiring error / transmitter failure Check wiring; replace the transmitter if necessary

Large measurement error Probe insertion depth insufficient / float corrosion Adjust insertion depth; replace the float with a corrosion-resistant one

Product Consultation: Anhui Chuchen Technology provides customized UHZ-158S-UK selection solutions. Contact us for free technical support: Phone:15212084600 | Email:394821307@qq.com | Website: https://www.ahacyb.com

Send Inquiry